Yesterday I spent a pleasant hour or so binding a new set of my Reader’s Diary books. Many of the books I make are sewn together with needle and thread, but this one uses a wire or spiral binding. It’s a 3 step process: punch the holes for all the pages and the cover using the machine, insert the spirally wire in the holes (machine doesn’t do that), and then press the wire loops closed (the machine helps with that — I stick the book in a slot in the binder and pull down on the shorter lever to apply even pressure to the spine).

I use the binding machine at the San Francisco Center for the Book — it’s great to live so close to a place with lots of equipment I can rent when I need it! Especially this one. I looked into buying a wire binder, but even the low end models are awfully expensive for the amount of use it would get. Tina Kay, who teaches workshops in using the binder, pointed out to me that the cheaper models only bind a fixed sized spine (usually 11″), and I would definitely want a binder that allows me to vary the spine size.

My friend Cathy Miranker runs the youth program at SFCB. She coordinates (as well as teaches) bookmaking classes in the public schools all over the Bay Area, from San Jose to Marin. She’s planning a summer bookmaking institute for teachers this summer — 3 days of bookmaking ideas. I’ve helped her document and photograph the books the kids make, and the stories and pictures are always amazing in their inventiveness (even kindergarteners). Be sure to take a look at the gallery of kids’ work that Cathy has assembled for the book center’s website. UPDATE: Check out Cathy’s blog about bookmaking and kids. My friend Cathy Miranker runs the youth program at SFCB. She coordinates (as well as teaches) bookmaking classes in the public schools all over the Bay Area, from San Jose to Marin. She’s planning a summer bookmaking institute for teachers this summer — 3 days of bookmaking ideas. I’ve helped her document and photograph the books the kids make, and the stories and pictures are always amazing in their inventiveness (even kindergarteners). Be sure to take a look at the gallery of kids’ work that Cathy has assembled for the book center’s website. UPDATE: Check out Cathy’s blog about bookmaking and kids.

I’m always trying to find paper that I can print on a laser or ink jet printer and then letterpress. Lots of paper for ink jet and laser printers isn’t cotton or archival or it’s coated. Text weight letterpress paper for books is often expensive per sheet and usually (at least for where I live) has to be mail ordered.

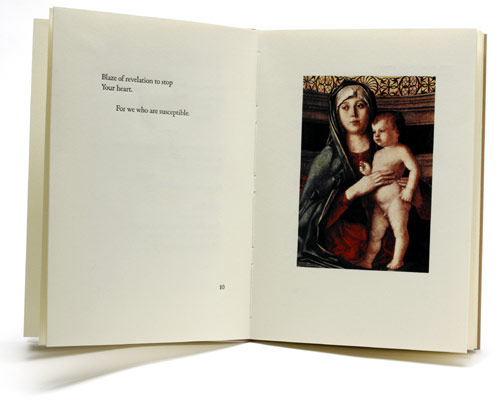

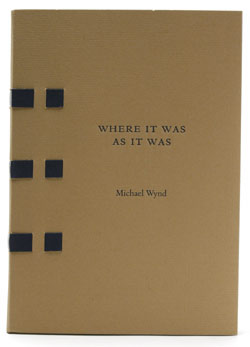

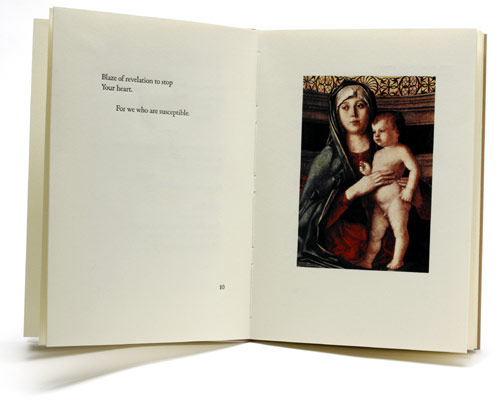

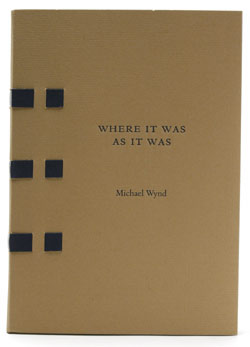

For this book I did of a friend’s poems, he wanted to include both photographs and letterpress. After some experiments, I found that the photos reproduced well on Mohawk Superfine using a color laser printer. I’ve used Mohawk Superfine for other letterpressed books, and it’s reasonably priced. Plus, I could get parent sheets from a local Kelly Paper, rather than mail order.

Making a hard bound book was going to be too expensive, so to make the binding special and affordable, we decided to sew the sections through the cover onto tapes and then weave the tapes into the front & back.

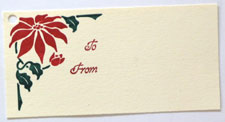

|  I teach letterpress printing at the San Francisco Center for the Book. In my class this past week, we printed these holiday gift tags, complete with a hole in the upper corner for a ribbon or string.

I teach letterpress printing at the San Francisco Center for the Book. In my class this past week, we printed these holiday gift tags, complete with a hole in the upper corner for a ribbon or string.