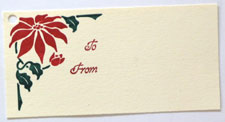

I teach letterpress printing at the San Francisco Center for the Book. In my class this past week, we printed these holiday gift tags, complete with a hole in the upper corner for a ribbon or string. I teach letterpress printing at the San Francisco Center for the Book. In my class this past week, we printed these holiday gift tags, complete with a hole in the upper corner for a ribbon or string.

To punch the holes, we used a lovely simple tool called a Japanese Screw Punch (it’s also called a Book Drill or Paper Drill). It cuts through multiple pieces of paper, and even thick stuff like mat board or davey board. Holes of different sizes can be made by swapping out the bits. The advantage over a hole punch is that you can position it anywhere on the paper, not just the edge, and there’s no guessing — you can see exactly where your hole will be placed. |

When the San Francisco Center for the Book got a

When the San Francisco Center for the Book got a